Resources

Carolina Filters specializes in the technical cleaning of various types of process equipment. From high value metallic filters, to heat exchangers unable to be cleaned in place, to highly-specialized process equipment, our technical capability supports nearly every industry.

Plate and Frame Heat Exchangers

Deep cleaning of Plate and Frame Heat Exchangers extends beyond Ultrasonics.

Cleaning Pipes, Valves, and Mixers

Did you know? Cleaning pipes and valves used in polymer processing systems presents several unique challenges due to the complex geometries of the parts and nature of the materials being transported.

Cleaning Fiber Spin Beams

Did you know? Solvent cleaning of fiber spin beams is a wonderful way to remove problematic polymer deposits.

Cleaning Breaker Plates

Did you know? Uncontrolled, high temperature burnouts of extrusion breaker plates can compromise delicate coatings on the breaker plate and result in part damage.

Cleaning Filter Assemblies

Servicing polymer melt filters goes beyond the cleaning of the actual filter elements. Proper cleaning of filter housings, stems, and tubesheets are imperative to ensure the highest level of product quality.

Cleaning Recycling Melt Filters

Over time, as recycling melt filters become terminally plugged with contaminants from the recycling stream, cleaning is necessary.

Cleaning Polymer Pumps

Polymer pumps are required for precise control, but if you don’t routinely clean your pumps, you risk production downtime.

Cleaning Column Packing

Cleaning metallic column packing is crucial to maintain the efficiency of the separation process.

Cleaning Polymer Dies

Carolina Filters offers specialized, non-abrasive cleaning methods that maintain the precision and integrity of a die’s design.

Cleaning Mist Eliminators

Mist eliminator screens become less effective as debris and contaminants build up, which can lead to contamination problems.

Cleaning Shell and Tube Heat Exchanges

Cleaning shell and tube heat exchangers involves a systematic approach utilizing a combination of high temperature oxidation, specialized cleaning chemicals, and thorough flushing.

Cleaning Gas Canister Filters

Gas canister filters are used in a wide range of industrial and commercial applications to filter and purify a gas stream.

Jelly and Candy Cooker Cleaning

Cleaning and inspection of cookers to ensure contaminant removal from tubes

Filtration of Post-Consumer Recycled Material

Technical cleaning of systems used to filter post-consumer recycled additives.

Ettlinger Screen Cleaning

Processing to recover filtration surface area & inspecting to verify cleanliness

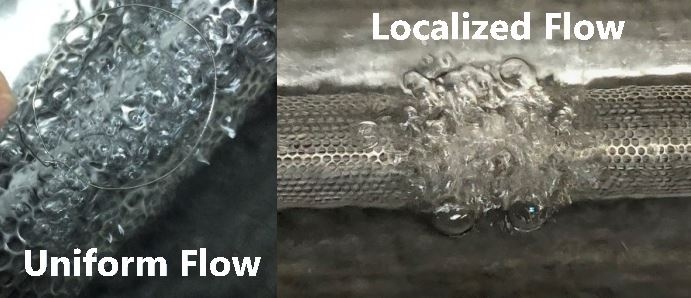

Enhanced Integrity Testing

Quantifying the degree of flow localization vs uniform flow across filter media

Cleanliness Testing for Metal Filters

Quantifying the degree of cleanliness in porous metal blowback filters

Bubble Point and Integrity Testing

Standardized test methods that validate and evaluate various filters for reuse.